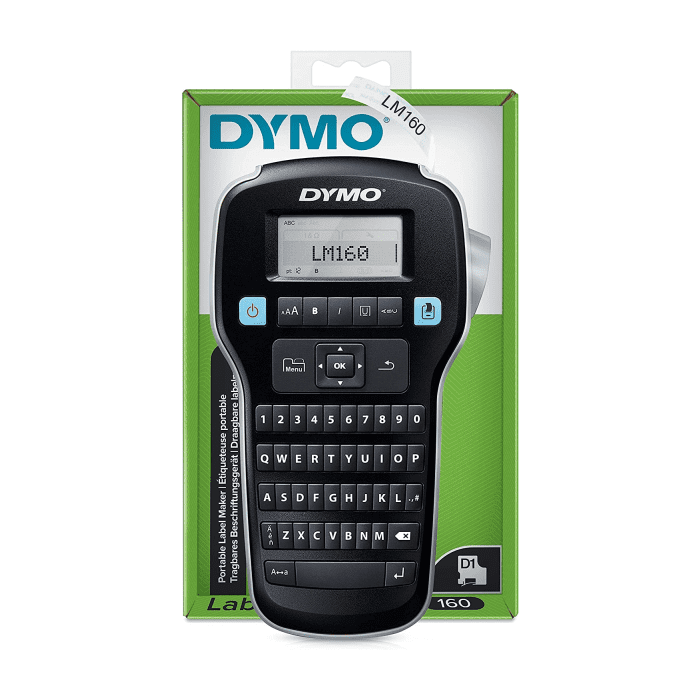

The Dymo LabelManager 160 is a versatile handheld thermal label printer designed to simplify everyday labeling tasks with ease and efficiency. In today’s fast-paced work environments, having a reliable device that quickly prints durable labels is essential for organization, tracking, and identification. This guide provides a deep dive into the Dymo LabelManager 160, answering frequently asked questions about its price, the cost of DYMO labels, font options, and reset procedures. By exploring these topics, you’ll gain a thorough understanding of the printer’s capabilities and how it can meet your labeling needs.

For those interested in learning more about this model, you can view details on the Dymo LabelManager 160 product page.

What Is the Price of the Dymo LabelManager 160?

When considering any piece of technology, price is a key factor. The cost of the Dymo LabelManager 160 can vary depending on where you purchase it, regional factors, and occasional promotional offers. Generally, the price of this handheld thermal label printer falls within a range that reflects its reliability and robust build quality.

Based on market trends and various retail outlets, the Dymo LabelManager 160 thermal transfer label printer typically costs between £80 and £120. This range accounts for slight differences in distribution channels and special deals that may occasionally be available. The price is competitive considering its functionality, durability, and ease of use. For the most current pricing information, checking with authorized distributors or the manufacturer’s website is advisable, as prices may fluctuate due to seasonal offers or stock availability.

Why Are DYMO Labels So Expensive?

A common question among users is why DYMO labels tend to be more costly compared to other generic label brands. Several factors contribute to the premium pricing of DYMO labels:

1. Quality of Materials

DYMO labels are produced using high-grade materials that ensure durability, clarity, and longevity. The label media is engineered to resist fading, moisture, and smudging. This high quality is especially important in environments where labels are exposed to challenging conditions—whether in industrial settings, healthcare facilities, or retail operations. The superior adhesive properties and resistance to chemicals also add to the overall manufacturing cost.

2. Advanced Manufacturing Processes

The production of DYMO labels involves advanced manufacturing techniques and stringent quality control standards. The process ensures that every label meets precise specifications for dimensions, color retention, and durability. These rigorous standards require investment in high-tech production equipment and quality assurance procedures, which are reflected in the cost of the final product.

3. Brand Reliability and Innovation

DYMO is a well-established brand known for its reliable and innovative labeling solutions. Over decades, DYMO has built a reputation for providing products that offer consistent performance and longevity. This level of reliability is particularly important for businesses that depend on accurate labeling for inventory management, asset tracking, and regulatory compliance. Customers are often willing to invest a bit more for a product they trust to perform consistently over time.

4. Economies of Scale and Support

The overall cost also includes support, warranties, and ongoing customer service. DYMO offers comprehensive support and often provides firmware updates and troubleshooting assistance. The assurance of dependable customer service and robust warranty programs can justify the higher cost of labels in the eyes of many businesses and professionals.

Thus, while DYMO labels may seem expensive at first glance, their cost is balanced by the benefits of superior material quality, advanced production standards, brand reliability, and comprehensive customer support.

Does the Dymo LabelManager 160 Have Different Fonts?

One of the features that set the Dymo LabelManager 160 apart is its versatile text formatting capability. When creating labels, the ability to choose from various fonts can greatly enhance the readability and aesthetic appeal of your labels.

Built-in Font Options

The Dymo LabelManager 160 comes equipped with a variety of built-in fonts designed to meet a range of labeling requirements. Users can choose from several pre-installed font types that vary in style, size, and weight. Whether you need a bold font for high-visibility labels or a more refined script for delicate items, this printer is engineered to offer practical options that suit everyday tasks.

Customization Features

While the device offers a fixed set of fonts, it does provide flexibility in adjusting font size and spacing. This means you can tweak the appearance of your labels to ensure that text is legible and formatted to your specific needs. Some users appreciate the simplicity of having a reliable, predetermined selection of fonts that have been optimized for clarity and durability on thermal media.

Practical Use in Various Environments

For instance, in a warehouse setting, using a bold and clear font is essential for readability from a distance. In contrast, a small office might benefit from a more understated typeface. The variety provided by the Dymo LabelManager 160 ensures that the labels produced meet both functional and aesthetic criteria, making it a suitable tool across different industries.

How Do I Reset My Dymo LabelManager 160?

At times, electronic devices like the Dymo LabelManager 160 may require a reset to clear errors, restore default settings, or resolve minor issues that interfere with normal operation. Here’s a step-by-step guide on how to perform a reset on your Dymo LabelManager 160:

1. Power Cycle the Device

A simple reset can often be achieved by performing a power cycle:

- Step 1: Turn off the device using the designated power button.

- Step 2: Remove the batteries or disconnect the power supply.

- Step 3: Wait for about 2-3 minutes to ensure that any residual charge dissipates.

- Step 4: Reinsert the batteries or reconnect the power supply.

- Step 5: Turn the device back on. This process often clears temporary glitches and returns the printer to normal functionality.

2. Factory Reset Procedure

If a power cycle does not resolve the issue, you may need to perform a factory reset. This process will restore the device to its original settings. The steps can vary slightly depending on the model, but a general method is:

- Step 1: With the device powered on, locate the ‘Clear’ or ‘Reset’ button. This is often found on the control panel.

- Step 2: Press and hold the ‘Reset’ button for several seconds (typically 5-10 seconds) until you see an indicator light change or a display message indicating that the reset is in progress.

- Step 3: Release the button once the reset sequence begins. Allow the printer a few moments to complete the process.

- Step 4: The device should now reboot with default settings restored.

3. Consult the User Manual

For more detailed instructions, always refer to the user manual specific to the Dymo LabelManager 160. The manual contains manufacturer-recommended procedures and troubleshooting tips that can help ensure that the reset is performed correctly without risking damage to the device.

4. Contacting Support

If you continue to experience issues even after a reset, it might be necessary to contact DYMO support or your retailer. Technical support can provide further guidance or facilitate repair services if needed.

Additional Considerations for the Dymo LabelManager 160

Ease of Use and Portability

The handheld design of the Dymo LabelManager 160 makes it particularly convenient for mobile work environments. Its compact size and intuitive controls allow users to print labels on the go, whether in a warehouse, retail environment, or office setting. The device is designed to be user-friendly, with straightforward navigation and clear display indicators.

Durability and Battery Life

Engineered for everyday use, the LabelManager 160 is built to withstand the rigors of frequent handling. Its robust construction and efficient power management ensure that it can operate effectively throughout the day. The extended battery life means fewer interruptions for recharging, which is critical in fast-paced work environments.

Applications Across Industries

The versatility of the Dymo LabelManager 160 extends to a wide range of applications. Whether you are labeling files in an office, organizing inventory in a warehouse, or marking equipment for maintenance, this printer offers reliable performance. Its durable output ensures that labels remain intact and legible over time, even in challenging conditions.

User Feedback and Market Trends

Market feedback on the Dymo LabelManager 160 highlights its reliability and ease of use. Many users appreciate the printer’s straightforward design, which minimizes the learning curve and allows for immediate productivity. The investment in quality DYMO labels, despite their higher cost, is often justified by the durability and clear print quality that the labels provide.

Conclusion

The Dymo LabelManager 160 is more than just a handheld thermal label printer—it is a tool that brings efficiency, reliability, and professional-grade output to everyday labeling tasks. Its competitive price range, typically between £80 and £120, reflects the quality and durability that users have come to expect from DYMO products. While DYMO labels might come at a premium, this cost is justified by the high-grade materials, advanced manufacturing processes, and exceptional longevity they offer.

The device’s built-in font options provide sufficient versatility for most labeling needs, allowing users to choose from several reliable, pre-optimized fonts that enhance readability and presentation. And when it comes to troubleshooting, resetting the Dymo LabelManager 160 is a straightforward process—whether by a simple power cycle or a more thorough factory reset—to ensure continued reliable operation.

In essence, the Dymo LabelManager 160 stands out as a dependable solution for anyone needing a portable, user-friendly, and high-quality label printer. Whether you are organizing office files, tracking inventory, or managing equipment, understanding the device’s pricing, label costs, font options, and reset procedures empowers you to maximize its potential and maintain operational efficiency.

For more detailed information and to experience the capabilities of this innovative printer firsthand, visit the Dymo LabelManager 160 product page. By investing in quality labeling solutions and staying informed on best practices, you can ensure that your labeling operations are both effective and cost-efficient—providing a solid foundation for enhanced productivity and organization in your daily work.